SCREW SPIKE

|

FISHPLATE BOLT

|

SHAFT

|

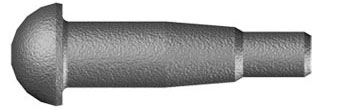

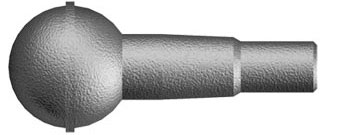

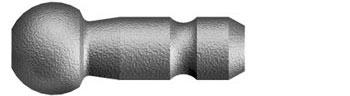

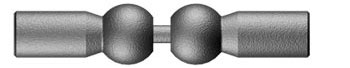

BALL PIN

|

LEVER

|

BALL PIN

|

BALL PIN

|

BALL PIN

|

BALL PIN

|

BALL PIN

|

LEVER

|

LEVER

|

NIPPLE

|

NIPPLE

|

LANCE

|

LANCE

|

LANCE

|

CUTTER BODY

|

CUTTER BODY

|

CUTTER BODY

|

CUTTER BODY

|

CUTTER BODY

|

CUTTER BODY

|

BELTECHNOLOGIA&M

MANUFACTURER OF EQUIPMENTFOR CROSS-WEDGE HOT ROLLING